Online Bio-Gas Analyzer

Application:

- Bio Gas analysis

- Digester gas research

- Engine feed gas analysis

- Sampling collection devices

Features:

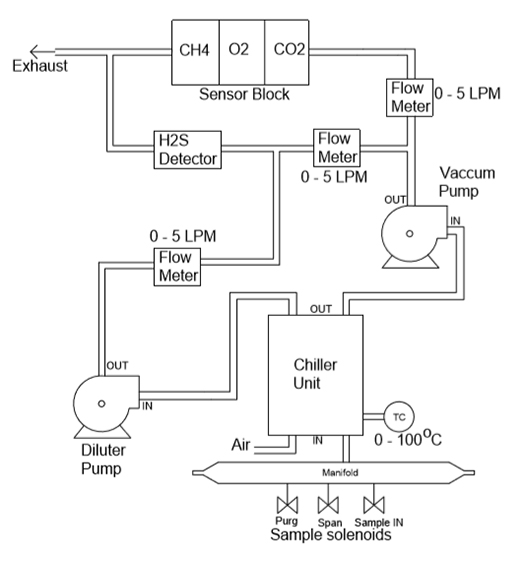

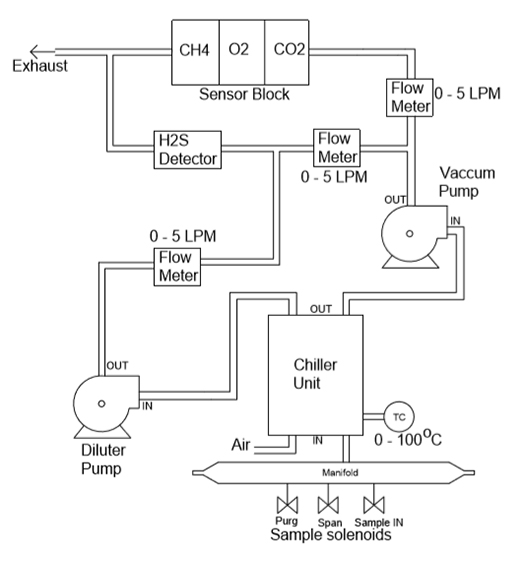

- Analysis of 4 gases CH4, H2S, CO2 and O2

- Configurable in dilution mode which enables to measure H2S in 2% Vol/Vol

- Up to 4 streams.

- Single panel to analyse gas before and after scrubbing with single set of sensors

- Built in sample conditioning system

- Both auto and manual mode of operation

- H2S scrubber for prolonging CH4, CO2 and O2 sensor life

- Data logging with timestamp onto USB and customer PC

- SCADA on customer PC for monitoring, control and data logging

- Colour touch display for gas monitoring and control

- Auto Calibration

- Inbuilt diagnostic mode

- Signal retransmission both digital and 4-20mA signals

- On display trends and graphs for analysis

- Programmable alarms

- Audio and visual alarms

User settable parameters:

| Sr. No. |

Parameter |

Value |

| 1. |

O2 High Value |

30% |

| 2. |

O2 Low Value |

0% |

| 3. |

CO2 High Value |

100% |

| 4. |

CO2 Low Value |

0% |

| 5. |

CH4 High Value |

100% |

| 6. |

CH4 Low Value |

0% |

| 7. |

H2S High Value |

20000ppm |

| 8. |

H2S Low Value |

0 ppm |

| 9. |

Operating Mode |

Auto/Manual |

| 10. |

Temperature Hysteresis |

2 |

| 11. |

Temperature Set point |

2 |

| 12. |

Chiller Drain On Time |

10 |

| 13. |

Chiller Drain Off Time |

30 |

| 14. |

Sampling On Time |

10 minutes |

| 15. |

Sampling Off Time |

30 minutes |

Specifications:

| General Specification |

| Type |

PLC based Multi-Channel analyzer system for measuring gas composition in biogas |

| Components to Measure |

CH4, CO2, O2 & H2S |

| Analyzer Housing Material |

M.S with Powder coating |

| Panel Dimensions (H x W x D) |

(1385x609x304) mm |

| Mounting |

Free standing panel |

| Mounting Accessories |

Inclusive (Wiringand piping to brought till panel) |

| Weather Protection |

Suitable for Outdoorapplication, IP-55 |

| Power Supply |

230VAC, 50Hz |

| System Type |

Sampling Type |

| Technique / Type of Sensor |

| For CO2 & CH4 |

Non Dispersive Infra Red (NDIR) |

| For H2S |

Electrochemical |

| For O2 |

Electrochemical |

| Analyzer Range |

| CH4 |

0 - 100% Vol. |

| CO2 |

0 - 100% Vol. |

| H2S |

0 - 2000 PPM |

| O2 |

0 - 30% Vol. |

| Multipoint sampling system |

Provided |

| No. of Stream |

Up to 4 |

| Suction Pump |

Diaphragm Pump |

| Process connection |

1/4" tube fitting |

| Wetted Part |

SS 316/ Teflon |

| Isolation Valve for Stream |

1/2" NPT(F) |

| Tubing & Tube Fittings |

1/4" tube fitting |

| Material |

SS 316/ Teflon |

| Tubing for Calibration gas / SS316 |

1/4" tube fitting |

| Flow Indicator |

Present in the system |

| Pressure Indicator |

Not required |

| Temperature Indicator |

Displays Dew Point of treated gas stream |

| Processed Gas (Recycled / Vented) |

Vented |

| Sensor Transmitter |

| Output |

Modbus and 4 nos. (4-20) mA Analog output |

| Comm. Protocol |

Rs. 485, Modbus Protocol |

| Alarm |

High and Low alarms, user programmable |

| Local Indicator |

Touchscreen HMI |

| Display type |

TFT Display |

| Display Size |

113 x 138 x 43 mm |

| Electronic Calibration Range |

As per service condition specified |

| Sensor Characteristics For NDIR technique |

| Overall Accuracy |

± 1% of full scale or Better |

| Zero/Span drift |

± 1% of full scale in 24 hours. |

| Response Time |

< 5 sec. for 90% response |

| Repeatability |

± 2 % of reading |

| Sensor Characteristics For Electrochemical technique |

| Overall Accuracy |

± 2% of full scale or Better |

| Zero/Span drift |

1% of full scale |

| Response Time |

< 15 sec. for 90% response |

| Repeatability |

± 2% of full scale or Better |

| Other Sensor Characteristics For Electrochemical technique |

| Linearity |

+/-' 2 % of full scale |

| Rangeability |

+/-' 2 % of full scale |

| Warm up Time |

< 3min |

| Single Cycle Time for each stream |

5 mins |

| Stability |

< 3 min |

| Relative Humidity |

90% non-condensing |

| Sensor Life Expectancy |

1yr for NDIR (depending on moisture and Conc of Biogas) |

| Electromagnetic Compatibility |

Shall be as per IEC 801 |

| Calibration System |

| Calibration gas cylinder (0.5LtrCanister) |

Optional |

| Capacity |

Mini. For 1 year |

| Purging gas (Automatic/Manuel) |

Auto |

| Purging gas Medium |

Instrument Air |

| Pressure / Temperature |

ambient/ ambient |

| Zero Calibration Type (Automatic / Manuel) |

Manual |

| Zero Calibration gas |

Instrument Air |

| Pressure / Temperature |

ambient/ ambient |

| Pressure / Temperature |

ambient/ ambient |

| Options |

| Sample Conditioning System |

confirmed for dust and moisture (Chiller Unit) |

| Touch Pad/Key padoper |

Keypad |

| Power consumption |

250 W |

| Booster Pump |

Provided |

| Earthing |

Provided |

| Surge / Lightning Protection |

Provided |

| Warranty |

12 months |

| Max. distance b/w sample tapping point & analyzer for good response time |

up to 200 meter is 1/4 inch line is used for sampling line |